Mobile Food Waste Processing System in 20-foot Container

A mobile system is design and setup for food waste processing. The whole system is powered by solar energy. Biogas produced from the food waste is collected in a tank, and then supplied to a biogas power generator. Electricity from the power generator is used to charge battery (shared with the solar panels).

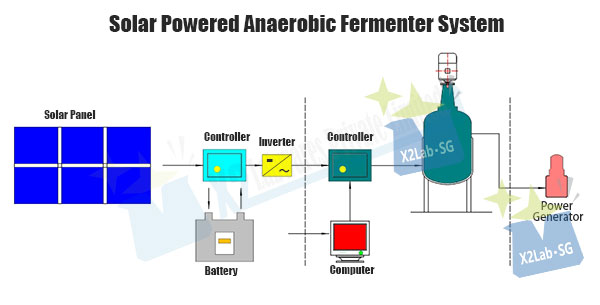

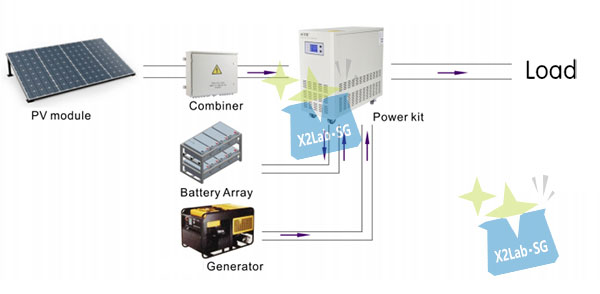

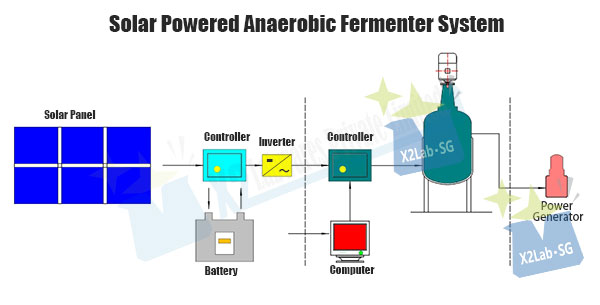

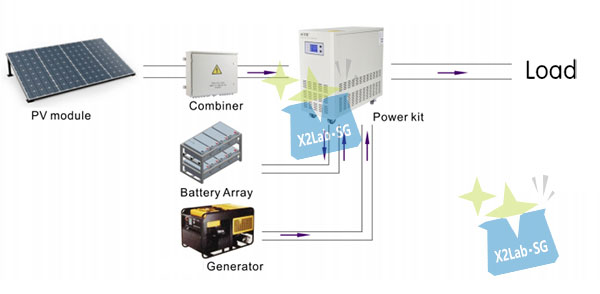

Hybrid Power Generation System (Solar and Biogas Power Generator)

- Solar panel installed on-top of the 20-foot container (330W Each)

- Inverter system (10KW)

- Accepts both solar power or AC power (from Biogas Power generator)

- Lead-Acid battery (18 * 150AH, 12V)

- Biogas Power Generator (5KW) - operated manually

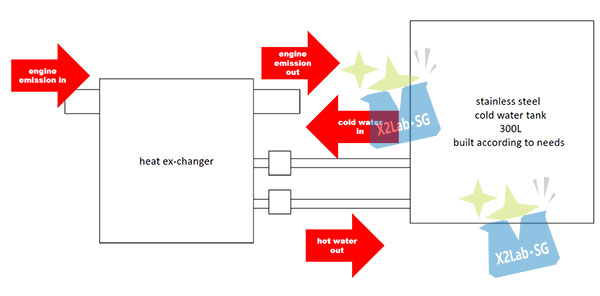

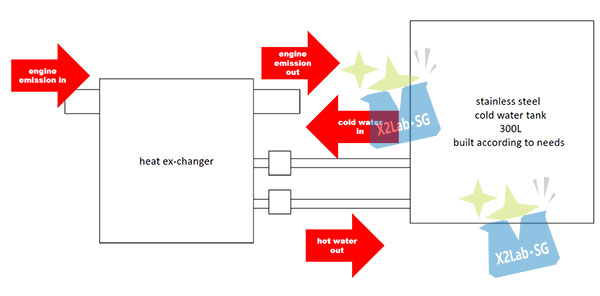

- Exhaust will pass through a heat-exchanger. The heat will be used to heat up water in the water tank.

- The water in the tank will be circulated to the external layer of main digester (heat-transfer).

Anaerobic Fermenter System

- Blender to crush the food waste

- A storage/feeder tank with stirring function, stores the crushed food waster temporarily before pump into the main digester.

- Main digester (1000L)

- Control System

- Monitors temperature in both main tank and water tank, pH value

- Manually controls all stirring and pump feature; or using following automatic settings

- Configure automatic / periodic pump of food waste into the main digester

- Configure periodic stirring of the material in the main tank

- When air pressure in main digester tank reaches preset value, it will trigger to pump biogas into the biogas storage tank

- Both the main digester and biogas storage tank are installed with safety valve, which will release the gas when pressure reaches preset value

Installation 🛠

The container was placed on a slope, with necessary support to keep container floor at horizontal level.

Gas Sensors and SMS Notification

Gas sensors and SMS notification system was also installed to report any emergency cases. Following gases are detected:

Summary

This is a fully customized design and installation for National University of Singapore. Please contact us for detailed information.

NUS News Release 🏆

🌏 NUS researchers lead effort to turn food scraps into green energy resource

🌏 NUS Project - Charging phones with food waste