Beijing XXBR (Xinxing Bairui) carbon support film, 300 mesh, imported copper grid (UK), 100 pcs/box.

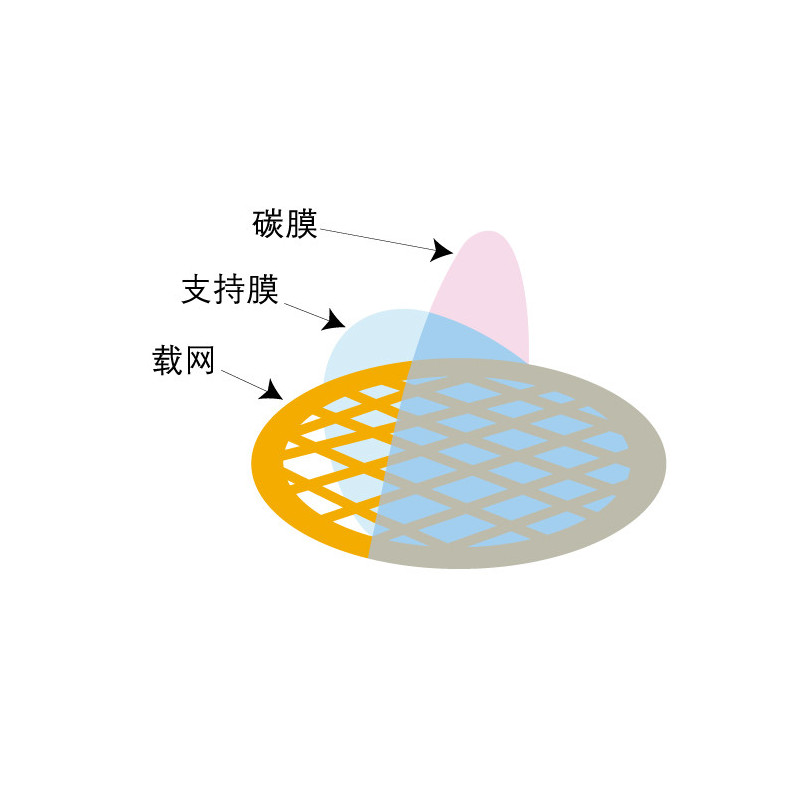

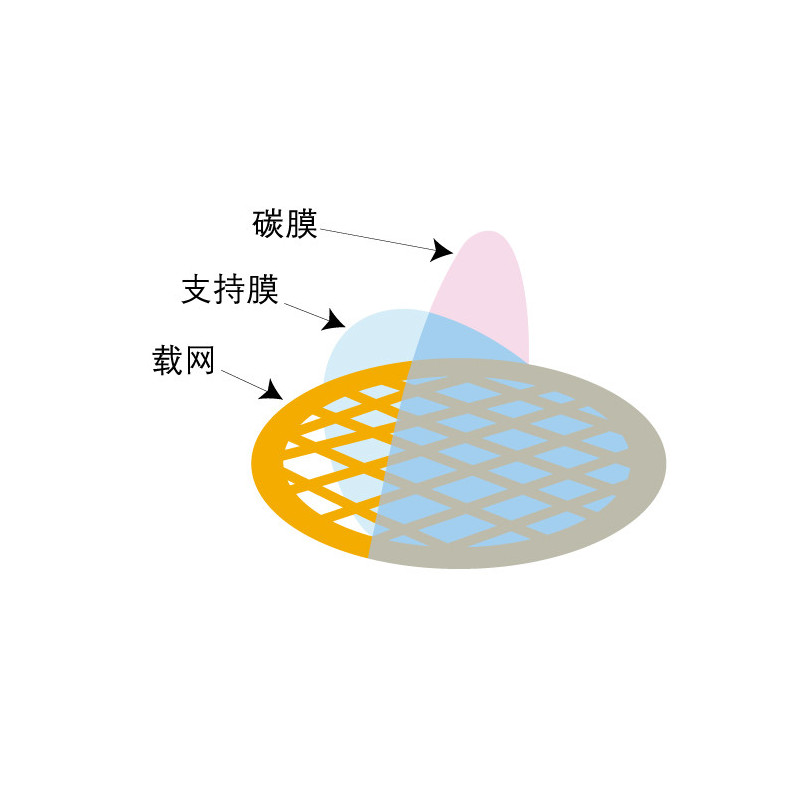

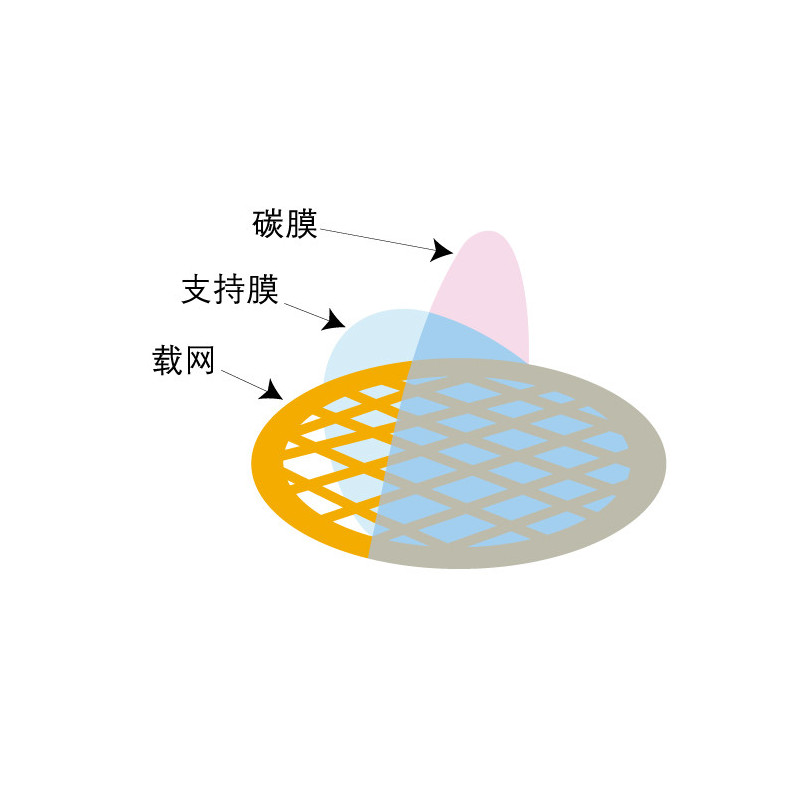

When a sample is observed under an electron microscope, the "support film on the grid" can accumulate charge under electron beam irradiation, leading to sample discharge. This can cause phenomena such as sample drifting, jumping, or even breakage of the support film. Therefore, to improve the conductivity of the support film and achieve better imaging, a layer of carbon is coated onto the support film. This carbon-coated support film is commonly referred to as a "carbon support film," and its typical thickness is 7–10 nm. Carbon support films are mainly composed of an organic layer and are quite thin, so they generally have minimal background interference. Usually, the support film is not corroded when dispersing samples in water or ethanol. The grid materials are typically nickel or molybdenum; if your sample is a magnetic powder, two methods can be used: (1) resin embedding and ultrathin sectioning; (2) using a double-layer carbon support film.